Need perfectly cut plywood parts without chipping or rough edges? Our plywood cutting and engraving service delivers tight tolerances, sharp details and consistent quality—ideal for architectural models, custom signage, jigs, furniture accents and branded décor.

Why laser technology is best for plywood cutting and engraving

-

Clean edges, minimal sanding: The laser seals edges on many plywood types for a neat finish.

-

Intricate shapes made easy: Fine text, lace patterns and complex geometry are produced with high accuracy.

-

No tooling costs: Digital files mean fast setup and easy revisions—perfect for custom jobs and short runs.

-

Repeatable precision: Every batch matches the last, ideal for kits, templates and modular builds.

-

Scalable workflow: From one-off prototypes to small production with efficient nesting to reduce waste.

Plywood Cutting and Engraving — what we offer

-

Max working area: 1200 mm × 880 mm (W × H).

-

Typical thicknesses: Common laser-friendly plywood sheets (e.g., 2–6 mm for detail work; thicker sheets subject to design & burn tolerance).

-

Grades & types: Poplar/birch craft plywood, laser-grade plywood, MDF-core ply (engraving), veneer-faced panels.

-

Finishes: Through-cuts, kiss-cuts, score lines, vector engraving, raster engraving for textures and logos.

Plywood Cutting and Engraving — use cases

-

Architecture & prototyping: Scale models, interlocking parts, façade studies, parametric pieces.

-

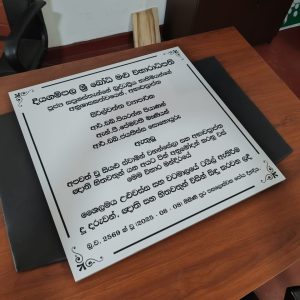

Signage & branding: Nameboards, logo panels, directional signs, menu boards, wall letters.

-

Workshops & manufacturing: Stencils, jigs, templates, tool shadows, fixture plates.

-

Gifts & décor: Plaques, ornaments, wedding décor, cake toppers, puzzle pieces, craft kits.

Advantages, possibilities & benefits

-

Design freedom: Create complex interiors, tight radii and fine perforations that are difficult with CNC saws.

-

Personalisation: Names, serial numbers, QR codes and graphics engraved directly onto plywood.

-

Better consistency: Vector-driven paths ensure sharp logos and repeatable outcomes.

-

Time & cost savings: No dies/moulds; quick edits reduce rework and wastage.

File prep & ordering

-

For cutting: Provide vector paths (AI, CDR, PDF, SVG, DXF). Convert fonts to outlines; merge/close paths.

-

For engraving: Supply high-resolution artwork (PNG/JPG/PDF).

-

Need help? Our in-house designing facility can clean up drawings, set line weights and nest parts.

-

Fulfilment: Colombo pickup or island-wide courier. Packed flat with protective sheets on request.

Note: Actual plywood cutting and engraving quality depends on plywood glue type, veneer species and thickness. We’ll advise the best settings after checking your sample or supplier spec.

There are no reviews yet.